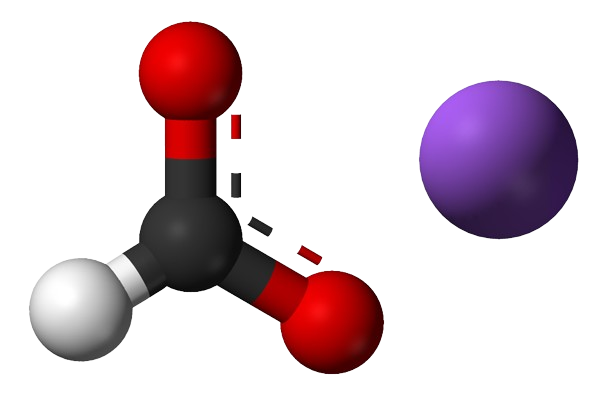

Sodium Formate

Sodium formate is a chemical compound with the formula NaHCOO. This white crystalline powder is the sodium salt of formic acid and has diverse applications across various industries. In the chemical industry, sodium formate serves as a versatile substance with notable properties. It is commonly used as a reducing agent in the synthesis of various organic and inorganic compounds. Furthermore, its hygroscopic nature makes it valuable in de-icing formulations and as an anti-icing agent for runway surfaces at airports.

- Process

- Applications

- Specifications

Manufacturing process: For commercial use, sodium formate is manufactured by absorbing carbon monoxide under pressure in solid sodium hydroxide at 130 °C and 6-8 bar pressure. This process produces a solution containing a molecular ratio of caustic soda to sodium formate above 1 to 1, continuing to react the carbon monoxide with the caustic soda until the molecular ratio of caustic soda to sodium formate in the solution does not substantially exceed 1 to 1.

CO + NaOH → HCO2Na

The low-cost and large-scale availability of formic acid by carbonylation of methanol and hydrolysis of the resulting methyl formate, sodium formate is usually prepared by neutralizing formic acid with sodium hydroxide. Sodium formate is formed as a by-product in the final step of the pentaerythritol synthesis and in the crossed Cannizzaro reaction of formaldehyde with the aldol reaction product trimethyl acetaldehyde In the laboratory scale, sodium formate can be prepared by neutralizing formic acid with sodium carbonate. It can also be obtained by reacting chloroform with an alcoholic solution of sodium hydroxide.

CHCl3 + 4 NaOH → HCOONa + 3 NaCl + 2 H2O

or by reacting sodium hydroxide with chloral hydrate.

C2HCl3(OH)2 + NaOH → CHCl3 + HCOONa + H2O

The latter method is, in general, preferred to the former because the low aqueous solubility of CHCl3 makes it easier to separate out from the sodium formate solution, by fractional crystallization, than the soluble NaCl would be.

- Intermediate Chemicals: Sodium formate chemically reduces other components by donating an electron or electrons. Formic acid and oxalic acid are prepared from sodium formate. Sodium formate is used in the manufacture of sodium hydrosulfite, a common reductive bleaching chemical.

- Reductive bleaching agent: Sodium formate is used to improve the brightness and color in dyeing/printing fabrics and paper.

- Tanning of leather: Sodium formate stabilize the chromium, resulting in better leather quality. It is used for better penetration and tanning time reducing.

- Deicing chemical: Sodium formate is less corrosive and undergoes fast melting action relative to other deicing chemicals.

- Buffering agent: sodium formate improves both desulfurization efficiency and increasing lime absorbent utilization. Sodium formate is also used in liquid detergent as a builder or an enzyme stabilizer. It is used in dyeing, in electroplating, in silage preservation.

De-icing and Anti-icing Agent: Sodium formate is utilized as a de-icing and anti-icing agent for roads and airport runways. It effectively lowers the freezing point of water, preventing the formation of ice and facilitating snow removal.

Leather Tanning: In the leather industry, sodium formate is used in the tanning process. It helps in the fixation of dyes and ensures uniform absorption of chrome, playing a crucial role in the production of high-quality leather goods.

Oil and Gas Industry: Sodium formate is employed in the oil and gas sector as a shale stabilizer in drilling fluids. It aids in reducing fluid loss during drilling operations, enhances the rheological properties of drilling muds, and helps maintain wellbore stability.

Chemical Synthesis: Sodium formate serves as a versatile reducing agent in various chemical synthesis processes. It is used in the production of formic acid, sodium hydrosulfite, and other organic and inorganic compounds.

Cleaning and Decontamination: Sodium formate is used in cleaning and decontamination processes, particularly in the removal of heavy metals from contaminated surfaces. Its ability to form stable complexes with certain metals contributes to its efficacy in these applications.

Food Preservation: In the food industry, sodium formate is employed as a preservative, helping to extend the shelf life of certain food products.

Heat Transfer Fluids: Sodium formate is used in the preparation of heat transfer fluids, especially in geothermal applications, due to its thermal stability and efficiency in heat exchange processes.

Textile and Printing Industry: Sodium formate finds application in the textile and printing industry as a reducing agent for dyeing and printing processes.

| PRODUCT IDENTIFICATION | |

| CAS NO. | 141-53-7 |

| EINECS NO. | 205-488-0 |

| FORMULA | HCOONa |

| MOL WT. | 68.01 |

| H.S. CODE | 2915.12 |

| TOXICITY | Oral, mouse LD50: 11200 mg/kg |

| SYNONYMS | Formic acid, sodium salt; Salachlor; Formate de sodium; Formic acid, sodium salt; Mravencan sodny; |

| PHYSICAL AND CHEMICAL PROPERTIES | |

| PHYSICAL STATE | White crystalline powder |

| MELTING POINT | 261 C |

| BOILING POINT | Decomposes |

| SPECIFIC GRAVITY | 1.92 |

| SOLUBILITY IN WATER | 97 g/100 g |

| NFPA RATINGS | Health: 2 Flammability: 0 Reactivity: 0 |

| FLASH POINT | Not considered to be a fire hazard |

| STABILITY | Hygroscopic. Readily absorbs moisture from the air |

| SALES SPECIFICATION | |

| APPEARANCE | White crystalline powder |

| PURITY | 95.0% min |

| NaOH | 1.0% max |

| NaCl | 1.0% max |

| NaCO3 | 3.0% max |

| NaS | 0.1% max |

| MOISTURE | 1.0% max |

| TRANSPORTATION | |

| PACKING | 25kgs in Bag, 20mts in container |

| HAZARD CLASS | – |

| UN NO. | Not regulated |